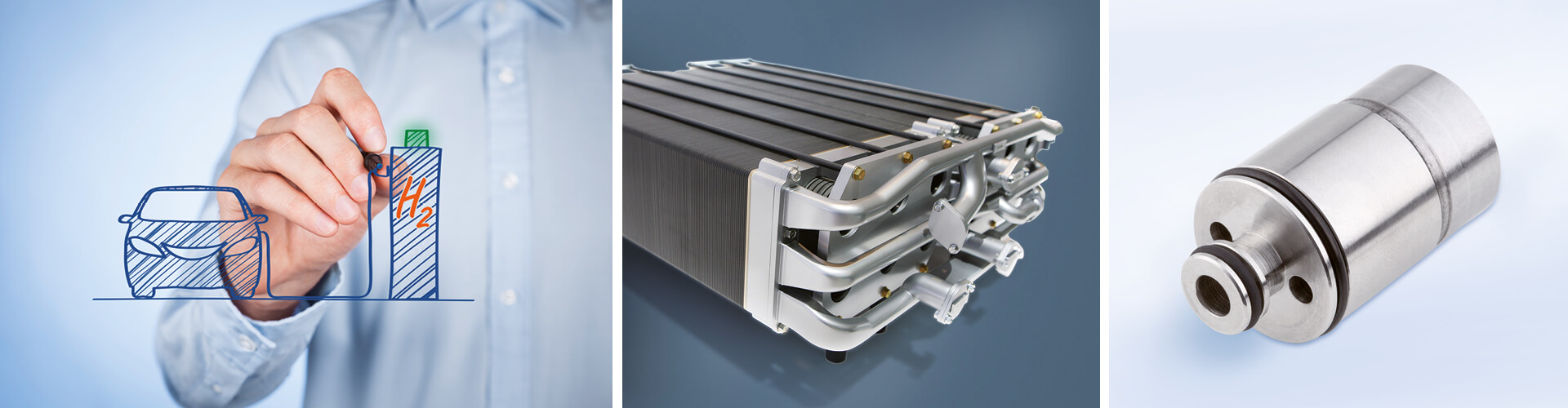

Valves are required in fuel cell systems to supply the gaseous fuel (generally natural gas or hydrogen) at the inlet side and to purge the condensate at the outlet side of the device. According to the initial pressure of the gas, the pressure will be reduced in several cascades.

Usually, two types of valves are embedded. On one hand the system needs on/off valves to drain condensate or to shut off the tank or the entire system. On the other hand, one proportional valve is required to dose the flow rate of gaseous fuel to the stack‘s inlet. Depending on the actual power demand, the gaseous fuel flow will be controlled through a highly dynamical proportional behavior.

Special requirements for valves

One of the most important requirements for the valves are low internal and external leakage in order to ensure high level of process stability and repeatability of the system. It is hereby also important to reduce the hydrogen consumption, also while in stand-by mode.

The embedded valves have to work precisely and reliably, especially under extreme conditions such as high or low temperatures, or under extreme vibration. At the same time, the valves must comply to safety requirement during the entire expected life time.

Fuel Cell Systems allow electrically driven vehicles to have an extended range with zero emissions.

Through the application on vehicles, valves within such fuel cell systems are exposed to extreme environmental conditions where these valves have to work absolutely reliably; last but not least because of the fact that hydrogen is typically used as propellant.

There are the following typical valve-requirements on vehicle fuel cell systems:

More and more electrical devices are used in our everyday life, such as consumer electronics, safety devices or medical technology. The operation time of these devices is always limited to the capacity of the integrated batteries.

Using micro fuel cell systems, such devices can operate much longer independently from the power grid and have a reduced system weight at the same time.

Portable fuel cell systems are typically run with a gas-cartridge which can be exchanged when necessary. Such systems need to be small and light weight, and are normally trimmed to low energy consumption. These requirements are directly assigned to the micro valves that dose the gaseous fuel into the micro stack.

Our 7 mm-Spider®-Valves are specially designed for micro dosing purposes.

The process waste heat of stationary fuel cell systems in buildings is fed into the heating circuit of the building. So, besides electrical energy, also heat is „produced“ out of natural gas through the fuel cell. This increases the effectiveness of the system while reducing emissions.

Stationary fuel cells are generally powered by natural gas, that is fed through pressure regulator valves precisely into the reformer unit of the system. Since such systems are typically installed within closed rooms, the valves must be absolutely gas tight, both internally and externally, which is also subject to the DVGW-approval. As part of a building equipment, the valve has to have a high level of life expectancy.

Also in such stationary system, one additional switching valve is integrated in order to periodically drain the condensate without releasing unconsumed gaseous fuel at the same time.

For more than 40 years Staiger is coining the evolution of valve technology and valve electronics essentially. More than 200 patents and utility patents result from innovativeness and technical creativity. Of course we know all the function principles of our standardproducts by heart. However, we focus the development of customized products:

Valve solutions including the necessary electronic control – custom fit according to the demands at competitive prices.

We create a value added valve solution out of our wide valve portfolio for you. Because our valves are based on our construction kit, we can react very flexibly on any demand in order to offer an economic solution to you.

As a matter of course, a valve, that has been customized for you, is exclusive for you. Only by means of exclusivity of the core components of your products, you can keep and improve your competitive advantage.

Your product is very special! It requires special components therefore.